Wheelabrator Group Peening and Surface Engineering Solutions

Wheelabrator Group is the world leader in the design and manufacture of surface treatment equipment. We provide automated and manual air blast, wheel blast, wet blast and vibratory finishing equipment, to prepare, clean, peen and polish components. Additionally, we also provide an expert sub-contract service for processing your components.

Aircraft engines and structures often require blasting, shot peening and mass finishing to strengthen the material, prepare the surface for further processes like plasma spray, reduce surface profiles and increase the operating life of critical components. Through our unique understanding of the precision and repeatability required, Wheelabrator Group treatment of aerospace and aircraft parts is a critical step in the manufacturing process.

Conformance to audits and specifications such as NADCAP, SAE, MIL, AMS are closely monitored and applied during the design of Wheelabrator Group equipment. Additionally, we provide the option of simple process controls in our peening systems as an alternative to equipment with more complex controls.

AIR BLAST, WHEEL BLAST, WET BLAST AND VIBRATORY FINISHING

For aerospace applications, we provide the following equipment and sub-contract services:

Fuselage / outer skins:

- Chemical-free selective paint stripping

- Rib peen forming, distortion correction and saturation peening

Wings:

- Peening stringers and spars

- Preparing surfaces prior to bonding

- Skin peen forming and saturation peening

Landing gear / components:

- Chemical-free depainting

- Surface etching and texturing

- Shot peening for fatigue life improvement and restoration

- Blast cleaning

Engines:

- Chemical-free depainting

- Removal of plasma coating

- Surface preparation

- Shot peening

- Blast cleaning

SHOT PEENING FOR AIRCRAFT COMPONENTS

Shot peening is used to induce residual compressive stress in the surface of components that are prone to cyclic and repetitive loads, such as landing gears, wing spars, wing ribs, stringers, engine blades, shafts and discs. This process can also reduce stress corrosion cracking.

There are two specialised processes derived from shot peening:

Shot peen forming: the natural effect of the process compresses and extends the superficial layer of the component causing it to bow. This process is used to form skins, access panels, wing flaps, fuselage sections, etc.

Correction of distortion: uses the same technique but in reverse. When a component is distorted due to machining or heat, shot peening is used to compress and stretch the local areas to achieve the required flatness. This is used for ribs, spars and other complex structural metallic parts.

WHEELABRATOR GROUP TECHNOLOGIES

Our technologies, coupled with our global experience, allow the Wheelabrator Group to service a wide range of requirements. Regardless of the size of the part to be processed or your productivity requirements, we will design and construct the appropriate surface engineering solution for your needs. Among other processes, our technologies are used to remove scale, paint, flashing, grease and burrs as well as peen, etch, polish, deburr and profile parts.

Besides aerospace applications, Wheelabrator Group technologies have been used for:

- Autosport: shot peening stub axles

- Automotive: cleaning / peening engines and engine components

- Railway: cleaning railway carriages

- Diecasting: deflashing parts

- Manufacturing: rust and scale removal from structural steel

- Medical: peening medical implants

- Optical: cleaning and polishing spectacle frames

- Mining: peening mining drill bits

- Speciality Metals: imparting surface profiles

Equipment and sub-contract services are regularly provided to most of the key Aerospace OEMs such as Airbus, Boeing, Bombardier, BF Goodrich, General Electric, Messier and Pratt & Whitney.

We hold various aerospace accreditations and supplier approvals.

Our internationally renowned products and services include Abrasive Developments, Clean-Tek, Impact Finishers, Schlick, Sisson Lehmann, Vacu-Blast, Walther Trowal and Wheelabrator.

Products and Services

Video

Related Projects

Bombardier Aerospace Q400 Dash 8

Bombardier Q300 DHC-8 Dash 8

Cessna SkyCourier 408 Turboprop Aircraft

Airbus A350 XWB

Gulfstream G500 Business Jet

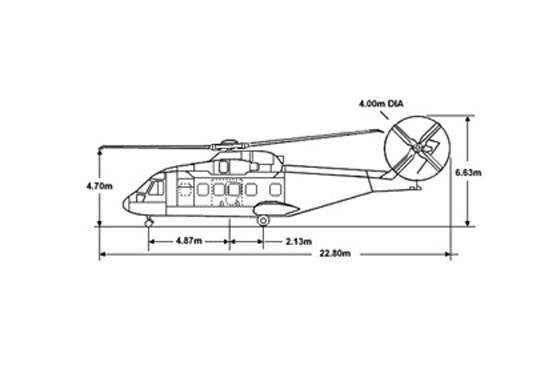

Airbus H175 Helicopter

ARJ21 Regional Jet Aircraft, China

AgustaWestland AW109 Power Light Multirole Helicopter

Boeing 777 Long-Range Wide Body Airliner

AgustaWestland Grand

Airbus A380-800F Wide-Bodied Freighter

Airbus A380 Superjumbo Airliner

Airbus A310-200F

Bombardier Global 5000

Boeing 737 Next-Generation (NG) Narrow Body Airliner

AgustaWestland AW119 Koala

Bombardier Learjet 31A

Bombardier CRJ200

Hawker Beechcraft Hawker 800XP

Hawker Beechcraft Hawker 400XP

Boeing 767

Airbus A340-600

Bell Agusta BA609

AgustaWestland AW139

Hawker Beechcraft Premier 1

Bombardier Challenger 604

Bombardier Challenger 300

AgustaWestland AW101 Medium-Lift

Bombardier Canadair 415 Superscooper

Hawker Beechcraft Hawker 4000

Airbus A330 Wide-Bodied Medium / Long-Range Twin-Engine Airliner, Europe

BAE 146

BAE Avro RJX

Airbus A320

Bombardier Learjet 45

Bombardier Global Express

Airbus A318

Airbus A340-200 and A340-300

BAE Avro RJ

Airbus A310

Airbus A300-600

Airbus A300-600ST Beluga

Bombardier CRJ700 Jet

Boeing 747-400 Intercontinental Airliner

Press Release

Wheelabrator Impact Finishers celebrated being the first shot peening subcontract supplier in the UK to win the supply chains for the 21st century (SC21) bronze award at the SC21 Task Force Conference at the Williams F1 conference centre in Oxfordshire.

Read moreA new video from Wheelabrator presents the team and the operations of the Wheelabrator Technology Centre, Metelen, in Germany.

Read moreWheelabrator engineers have developed a new Robot Peener to deliver three times faster process time with complete process reliability.

Read moreWheelabrator Plus is pleased to have continued its important certification AS / EN 9100 aerospace quality management system accreditation to perform sub contract finishing of customer parts at its Birmingham site.

Read moreWheelabrator has extended its successful Module8 concept for a new generation of wet blast machines.

Read moreWheelabrator is delighted to add another important certification to its portfolio by recently gaining the prestigious AS /EN 9100 aerospace Quality Management System accreditation to perform sub contract finishing of customer parts at its Birmingham site. Not only has it achieved this high-status

Read moreHigh pressure and extreme temperatures are definitely something that materials sent into space need to cope with. The fuel tanks for the European carrier rocket “Ariane” are an important component of the aerospace project and have high complexity and extraordinary safety requirements.

Read morePeen forming by blasting with steel shot is now carried out by Dassault Aviation at their Seclin site (northern France) to correct the distortion of mechanical parts after their shapes have become altered during the manufacturing process, or to complete the shape of the Falcon 7x wing panels afte

Read moreUnder the Ministry of Defence, specifically the Air Force, Atelier Industriel de l‘Aéronautique (AIA) based in Bordeaux, France is responsible for the industrial maintenance and overhaul of the Aeronefs engines. AIA had to renew their shot blasting machines as most of their equip

Read moreWheelabrator continues to provide innovative peening solutions to Skills Inc., in its Auburn, Washington facility. With a September 2008 installation of a Wheelabrator Inline Peening machine; this is the company’s second Wheelabrator installation in 3 years. Skills Inc., a supplier to major aircr

Read moreThe Wheelabrator Technology Centre in Charleville-Mézières, France, designs, develops and manufactures a wide range of a multi-axis shot peening equipment. In addition to their renowned MP range (CNC machines), the MPR (robotised shot peening machine) range offers optimal solutions for various sh

Read moreWheelabrator Group has successfully delivered and commissioned a MPD 15000 CNC peen forming machine to Beijing Aeronautical Manufacturing Technology Research Institute (BAMTRI) in August 2008. This equipment was mainly used for the peen forming and shot peening of large aircraft compone

Read moreLeading manufacturer GKN Aerospace Transparency Systems is flying through the cleaning process at its UK site in Birmingham. Thanks to Wheelabrator Group, it has seen a 66 per cent reduction in the time taken to remove oxides from tooling parts at its factory in Kings Norton, UK. GKN Aerospace pu

Read moreShot peening is a cold working process used to enhance the fatigue resistance of highly stressed metallic components such as compressor blades, aircraft structural parts and transmission systems. Any metallic component that is subjected to cyclic stresses within its elastic limit can benefit from

Read moreA quality blast result is key to customer satisfaction, but it is not the only deciding factor for aerospace companies when making equipment purchasing decisions. Efficiency and cost are also high on the priority list. The double-frame technology blast machine from Wheelabrator Group offers you f

Read moreImpact Finishers, the sub-contract division of Wheelabrator Group has passed an in-depth examination to receive the aerospace industry’s acclaimed NADCAP accreditation. The distinction applies to Impact Finishers sub-contract shot peening facilities in the UK at Slough and Coventry. La

Read moreThe Wheelabrator Group Technology Centre in Charleville, France, specialises in the development and manufacturing of shot-peening machines and 'airblast precision equipment' dedicated to the aerospace industry. The range, principally CNC machines and robotic systems, offers a set of successful an

Read moreIn 2002 MTU Maintenance bought surface preparation equipment from Wheelabrator Group for their new plant in Zhuhai China. The package included one shot blast machine, one shot peening machine, two wet blasting/peening machines and four hand blasting cabinets. Three years later MTU came

Read moreStressed out aerospace companies can take to the skies after Wheelabrator Group announced it had signed an exclusive deal with high-tech French peening specialists Sonats, bringing a new range of machines to Asia. Sonats' innovative technology is similar to traditional shotpeening processes, usin

Read moreThe Wheelabrator Group has successfully delivered and commissioned a wing-peening system for the XAIC aircraft-manufacturing company, located in X'ian, China. The new MP 20,000 machine will be mainly used for peen forming and saturation strengthening of wing-skin panels of large-sized civil airpl

Read moreThe Wheelabrator Group has successfully delivered and commissioned a wing-peening system for the XAIC aircraft-manufacturing company, located in X'ian, China. The new MP 20,000 machine will be mainly used for peen forming and saturation strengthening of wing-skin panels of large-sized civil airpl

Read moreRegional Offices

41 Craven Road

Altrincham

WA14 5HJ

Other

United Kingdom

Unit No. 1103, 11/F Futura Plaza 111-13

How Ming Street KwunTong

Kowloon

Hong Kong

China

Rectángulos No. 214 Parque Industrial Arco Vial

C.P. 66000 Garcia N.L.

Mexico

Gran Via de les Corts Catalanes 133 - At B.

ES-08014 Barcelona

Spain

1606 Executive Drive

LaGrange

GA 30240

United States of America

Burlington Technology Center

1219 Corporate Drive

Burlington

L7L 5V5

Ontario

Canada

Heinrich-Schlick-Strasse 2

D 48629 Metelen

Germany

Unit 03, 11th Floor., Futura Plaza

111-113 How Ming Street

Kwun Tong, Kowloon, Hong Kong SAR

Other

Hungary

Ul. Malakhitovaya, 27, Building B

129128 Моscow

Russia

Biuro Handlowe, ul. Rzymowskiego 30 lok. 318

PL-02-697 Warsaw

Poland

41 Craven Rd

Altrincham

WA14 5HJ

United Kingdom

5th Floor, Kushal Garden Arcade

1A Peenya Industrial Area

Peenya 2nd Phase, Bangalore 560058

India

24, rue Camille Didier BP 39

F-08001 Charleville-Mézières Cédex

France

28-29 rue de Tournenfils

F-91540 Mennecy

France

Ferdinand-Porsche Str. 23

D- 51149 Köln

Other

Germany

Za Balonkou 269

CZ-260 01 Príbram 1

Czech Republic

Verlorenbroodstraat 63B

BE-9820 Merelbeke

Belgium