Brüel & Kjær Aircraft Noise and Vibration Testing Solutions

A leading manufacturer of high-quality noise and vibration measurement solutions for R&D, production and operational applications, Brüel & Kjær helps aerospace engineering companies become more efficient in their production time and reduces development periods with user-friendly and cost-efficient testing.

Complete noise and vibration measurement equipment

Supplying complete sound and vibration measurement equipment from a single point of contact, Brüel & Kjær manufactures high-quality transducers, data acquisition hardware, vibration test systems and analysis software backed by a comprehensive global service and training organisation.

Exterior noise certification, ramp noise testing and wind tunnel testing

High-quality testing assumes greater significance as new materials and designs must pass an exterior noise assessment. Brüel & Kjær performs air craft noise certification and air vehicle flyover noise measurements. During the R&D stage Brüel & Kjær microphones, accelerometers and data acquisition systems provide exterior noise identification, ramp noise testing and wind tunnel testing.

Interior noise assessment of helmets, cabins and cockpits

Optimising comfort and noise reduction, Brüel & Kjær has solutions for comprehensive interior noise assessment of helmets, cabins and cockpits. A range of noise source identification products such as noise mapping and source path contribution analysis assist in R&D and troubleshooting, while occupational health and safety standards testing is addressed with human acoustic and vibration monitoring products.

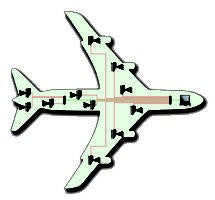

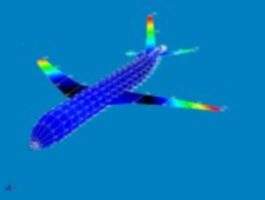

Structural dynamics testing for aircraft

Analysing and helping with the design of airframe structures, Brüel & Kjær’s structural dynamics testing encompass modal analysis and virtual model validation and updating for finite element analysis. Operational testing such as vibration troubleshooting and ground vibration tests are covered by a range of scalable systems.

Vibration testing for aircraft safety and durability

Vibration testing for lifetime durability, fatigue limit and acoustic fatigue testing are all part of Brüel & Kjær’s integrated aircraft safety and durability solutions. Systems for flight testing and monitoring integrate with field data replication capabilities for shock response and crash testing.

Engine noise, source location, analysis and certification

Brüel & Kjær’s tools cover the entire design process for engine noise, with detailed noise source location and analysis for the development of engine sound quality and acoustic lining designs. Engine noise certification is a core competence for the company’s solutions.

Aircraft engine health monitoring

Portable and permanently installed sensors monitor the mechanical health of equipment, engine and gearbox conditions for preventative maintenance and manufacturer-specified checks. Brüel & Kjær makes systems for balancing, trim balancing and vibration diagnostics, as well as monitoring of modal parameters.

Engine component durability testing

Ensuring the quality of new material applications with modal testing guarantees the durability of engine components. Equally, life-cycle vibration testing of components, or whole assemblies, qualifies test objects up to entire engines. The same mechanical shaker systems perform fatigue testing for weakness identification.

Brüel & Kjær has over six decades’ experience of providing innovative solutions for noise and vibration testing:

- More than 90 sales offices in 55 countries

- 12 accredited calibration centres

- R&D engineers in Denmark, UK, US and India

- Brüel & Kjær University with over 500 training courses per year

Products and Services

Video

White Papers

Related Projects

Press Release

The sound and vibration company's courses range from theoretical-based introductions to practical sessions, including the Theory and Practice of Noise Measurements course.

Read moreBrüel & Kjær and Sikorsky Aircraft Corporation have signed a memorandum of understanding (MOU) to strengthen industrial cooperation between the two companies.

Read moreBrüel & Kjær to supply Pratt & Whitney with a static engine certification test (SECT) system.

Read moreINTA (National Institute for Aerospace Technology) has recently acquired an array-based noise source identification system from Brüel & Kjær.

Read moreVirginia Polytechnic Institute and State University has opened its new 'Brüel & Kjær Laboratory for Aerospace Vibration and Acoustics'.

Read moreAfter investing in a vibration test system, the engineering team at Carlisle Interconnect Technologies has benefitted greatly from its new range of testing capabilities.

Read moreSound and vibration specialist, Brüel & Kjær is participating at several technical trade shows in the UK during May.

Read moreFriday 20 April saw the inauguration of the Vibration and Acoustic Laboratory & Future Energy Initiative at Lund Institute of Technology in Sweden.

Read moreBrüel & Kjær offers advanced test-to-Finite Element Analysis (FEA) tools to help aircraft and vehicle manufacturers speed up their time-to-market process.

Read moreBrüel & Kjær Vibration Test Systems (VTS) will be presenting one of the sessions at this year's Best Factory Awards Conference, running on 27 - 28 March 2012 at Chesford Grange, Kenilworth.

Read moreEnvironmental health officers can now use live internet connectivity to remotely monitor investigation progress with Bruel & Kjaer's 'Matron Live' Neighbour Noise Monitoring system.

Read moreAssessing vehicle noise is a faster and easier process with the launch of Brüel & Kjær's latest data analysis software platform, PULSE 16.1.

Read moreVisitors to the Institute of Acoustics' (IOA) Wind Energy meeting will have a chance to see noise specialist, Brüel & Kjær's latest environmental tools.

Read moreVisitors to IMAC XXX will have the opportunity to discuss their technical needs with Brüel & Kjær's expert engineers during the five-day event.

Read moreBrüel & Kjær's real-time noise monitoring subscription service, NoiseSentinel, is set to ensure the compliance of the Crossrail construction works.

Read moreLeading sound and vibration expert, Bruel & Kjaer has announced the launch of the 2012 training calendar, which offers a mix of theoretical and practical classes.

Read moreBrüel & Kjær has successfully completed the Factory Acceptance Test (FAT) of a data acquisition and vibration test system for INPE, Brazil.

Read moreBrüel & Kjær is pleased to announce that it has been chosen to supply NoiseDesk, its latest noise and flight track monitoring service, to London Southend Airport.

Read moreAssessing the power and location of noise sources has become easier with the 2270-G, a unique system available from Brüel & Kjær which uses sound intensity techniques.

Read moreVisitors to the Aero Engineering show at Birmingham's NEC, held on the 9-10 November 2011, will have the chance to meet Bruel & Kjaer UK's technical team.

Read more