TITAL Titanium Investment Castings, Aluminium Investment Castings, HERO Premium Casting® and Rapid Prototyping

TITAL is a leading company for titanium and aluminium alloy investment castings, located in Germany. Using the patented HERO Premium Casting® process, TITAL delivers lightweight, high-strength investment castings that can be supplied "ready-for-integration" and enable significant cost savings and many other benefits to the customer.

The main applications are within the following industries: aerospace, defence, electronics, optical, med-tech, Formula One and mechanical and civil engineering.

All processes are approved by PRI NADCAP and AS 9100. Quality testing is carried out according to all standard specifications. The castings are subjected to radioscopic, X-ray metallurgical and UV-penetrant examinations to detect any interior or exterior defects.

TITAL’s quality assurance manual fulfils the requirements of the German Association of Aerospace Industries and NADCAP. TITAL has a strong research and development ability for leading / future applications.

Investment castings ready for integration

Most castings are supplied ‘ready-for-integration’, avoiding costly and time-consuming handling and machining operations by the customer.

The integration of many design elements in one casting results in potential cost savings for the customer.

Design-to-cost

TITAL provides advisory support in part design and material selection, and assures close contact between the customer and TITAL throughout the entire process (i.e. concurrent engineering). Regular workshops for customer designers are held at TITAL site’s in order to optimise design-to-cost activities.

Hero Premium Investment Casting (aluminium)

The HERO Premium Casting® process combines an innovative, intelligent and robust process technology with a high reproducibility of aluminium investment castings. The results are lightweight, high-strength, complex castings which meet the design requirements of tomorrow.

TITAL has been certified by Airbus as the only investment casting company worldwide to cast critical parts with casting factor (CF) 1.0 in accordance with FAR-AC-25.621.

The patented HERO Premium Casting process differs from traditional casting processes through controlled computer-assisted solidification of the component. The advantages of this investment casting process include cost savings, excellent material soundness, process automation, high mechanical properties and a reduced risk of defects. Further advantages include:

- Lower weight through casting factor 1.0

- Thin wall thicknesses (up to 1.5mm, locally down to 1mm)

- Complex geometry of castings (back drafts)

- Reproducibility and dimensional accuracy

- Full process control along the complete value chain (SAP)

- Fully machined and surface treated; ready for integration

- Reliable preventive quality assurance

- Reduction in time and cost of testing

- Component size for aluminium parts, diameter approximately 1,800mm x 1,800mm x 600mm

- Weight: up to 80kg

- Alloys, e.g. A357, A356

Vacuum investment casting process (titanium)

- Cold moulds lead to faster solidification and higher mechanical properties

- Argon atmosphere for less α-Case

- Complex geometry of castings (back drafts)

- High mechanical properties

- Excellent material soundness

- Reproducibility and dimensional accuracy

- Component size for titanium parts, diameter approximately 1,000mm x 1,000mm x 600mm

- Alloys: TiAl6V4, Ti6242

- Weight: up to 300kg

Rapid prototyping in titanium and aluminium investment casting

Investment castings on the basis of rapid prototyping models cut development lead-time and provide flexibility at the customers’ R&D department. The advantages are:

- Same mechanical properties as serial production

- Separate production line for short delivery times

- Saving of development costs

- High flexibility

- Nearly same dimensional properties as serial production

About TITAL

TITAL supplies industry leading companies around the world in the field of aerospace, defense, motor sport and industrial systems with sophisticated aluminium and titanium investment casting products using the lost wax process.

TITAL was founded in 1974 and in 2006 the management took over the company. Today the company employs more than 500 people with 2011 revenue of €53M.

Products and Services

Video

White Papers

Investment Castings for Aerospace

TITAL is an industry leader in the manufacture of titanium and aluminium investment casting products. From our headquarters in Bestwig, Germany, we supply customers around the world in the fields of aerospace, electronics, optics, industrial and medical systems, Formula 1 racing and general motor sports.

TITAL: Company Brochure

We are an industry leader in the manufacture of titanium and aluminium investment casting products.

Related Projects

Embraer 190

Dassault Falcon 900EX

AgustaWestland AW109 Power Light Multirole Helicopter

Airbus A380 Superjumbo Airliner

ATR 72 Twin Turboprop Passenger Aircraft, Europe

Avions de Transport Regional’s ATR 42

Saab 2000

Boeing 737 Next-Generation (NG) Narrow Body Airliner

Eurocopter EC 135

Dassault Falcon 50EX

Embraer ERJ-145

Embraer ERJ-135

Airbus A340-600

Embraer 170

Dassault Falcon 900C

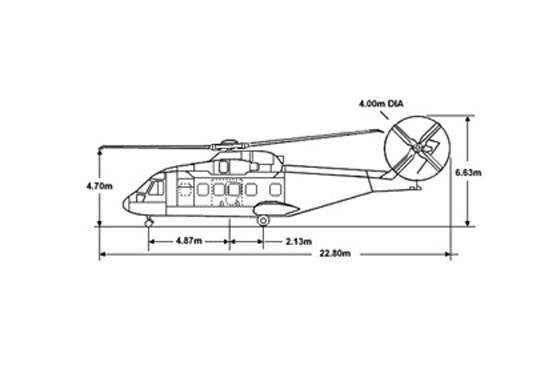

AgustaWestland AW101 Medium-Lift

Airbus A318

Airbus A340-200 and A340-300

Airbus A330 Wide-Bodied Medium / Long-Range Twin-Engine Airliner, Europe

Airbus A320

Airbus A310

Airbus A300-600

Ariane 5

Fairchild Dornier 328

Press Release

TITAL and Rolls-Royce recently signed a memorandum of understanding foreseeing the permanent development and production of highly complex aluminium and titanium investment castings for aircraft engines.

Read moreThe Investment Casting Specialist TITAL is happy about the increased interest of the motorsport industry in innovative aluminium and titanium investment casting components.

Read moreThe use of titanium investment castings in aircraft construction not only saves weight and fuel during flights, but is already very energy efficient, economical and environmentally friendly in the production process, with significant advantages in terms of CO2 emissions. These are the

Read moreThe titanium and aluminium investment casting specialist TITAL GmbH has been certified by Airbus according to General Requirements for Aerostructure and Material Suppliers (GRAMS). TITAL has met all the requirements in its first attempt to become a supplier for the new Airbus passenger

Read moreThe titanium and aluminium investment casting expert TITAL GmbH was able to prove with a pilot batch that beta annealing as a special heat treatment for titanium investment castings is probably not necessary. In doing so, TITAL takes up an adverse stance against the prevailing requireme

Read moreDuring the past few years the titanium and aluminum investment casting specialist TITAL located in Bestwig, Germany, has convinced many of its aerospace customers to use near-net-shape castings. At Airbus alone 40 machined parts have been converted into near-net-shaped castings in the last four y

Read moreAluminium and Titanium investment casting leader TITAL GmbH was recently qualified by Airbus France for the assembly of Titanium castings.TITAL has earned the position of a strategic supplier and will be gradually qualified for further component processing. The reason for the change in the p

Read moreThe titanium and aluminium investment casting specialist TITAL GmbH located in Bestwig, Germany, concludes its investment programme for the large titanium casting facility, which was put into operation in December 2008, with a new chemical milling facility. In the new facility titanium parts with

Read moreThe specialist in big-size titanium and aluminium investment, castings TITAL from Bestwig, Germany, succeeded in reducing the scrap rate of a Eurofighter part by 30% at the customer's shop floor. In cooperation with their British customer BAE Systems, TITAL succeeded within only 10 mon

Read moreThe German precision casting expert TITAL, based in Bestwig, Germany, has engaged in a partnership with the Institute ACCESS of RWTH, Aachen and other industry partners on a research collaboration. The goal being to dovetail scientific knowledge and practice and develop an efficient casting proce

Read moreTITAL, Europe's largest titanium casting manufacturer, will exhibit at Aero India 2009. TITAL has high expectations and will show mid-size titanium and aluminium casting at their stand in hall C, booth C26.15. In January TITAL began operating its new titanium investment castings furnace

Read moreThe recent Investment Casting Days in Bestwig, which was sponsored by the TITAL foundry, concentrated on cost reduction, assembly-ready investment castings and increasing quality requirements. The Investment Casting Days at TITAL is a regularly scheduled workshop for development and design engine

Read more"The agreement represents one of the most important orders in TITAL's® 30 year history," said Philipp Jerusalem, Tital Director of Sales and Marketing. "This order will contribute to a strong financial backlog, provide a sustainable base for the growing production capacity and also provid

Read moreUse of Titanium-Investment Castings with Casting Factor 1.0 for Airbus Germany, A380-parts Although castings have been found to be cost-effective already during the 1950's, their usage in critical aircraft structures was limited due to the imposition of a margin of safety. In tho

Read moreBestwig – Titan-Aluminium-Feinguß, well known as Tital®, recently reached two important contract conclusions. With the American customer Honeywell E&S, the delivery of titanium and aluminium investment castings for the APU-project were focused for the coming y

Read moreTitan Aluminium Feinguß (TITAL®) is a leading supplier of investment casting products in titanium and aluminium alloys. From its headquarters in Germany, TITAL supplies customers around the world in the fields of aerospace, electronics, optics, industrial and medical systems, Formula O

Read moreTitan Aluminium Feinguß GmbH (TITAL) is a leading company for titanium and aluminium alloy investment castings, located in Germany. Using the patented HERO Premium Casting® process, TITAL delivers lightweight, high-strength investment castings that can be supplied "ready-for-integration" and enab

Read moreDZ Equity Partner GmbH and the management team jointly acquired 100% of the equity of Titan Alu-minium Feinguß GmbH (TITAL®). TITAL is one of the leading suppliers of investment casting products in titanium and aluminium alloys in Europe. From its headquarters in Bestw

Read moreAfter the successful participation at the Paris Air Show in Le Bourget, Tital will exhibit during the Euromold in Frankfurt from 30th of November until 3rd of December 2005. We are pleased to invite you to visit us in hall 8 on stand no. L06. Please do not hesitate to contact us to set up a perso

Read moreJust in time for the Paris Air Show in Le Bourget, TITAL - Titan Aluminium Feinguß GmbH released the new website in three languages for its customers. Beside information on the company, business fields and production technologies the visitor will find additional news and useful downloads.

Read moreRegional Offices

Kapellenstr. 44

59909 Bestwig

Other

Germany